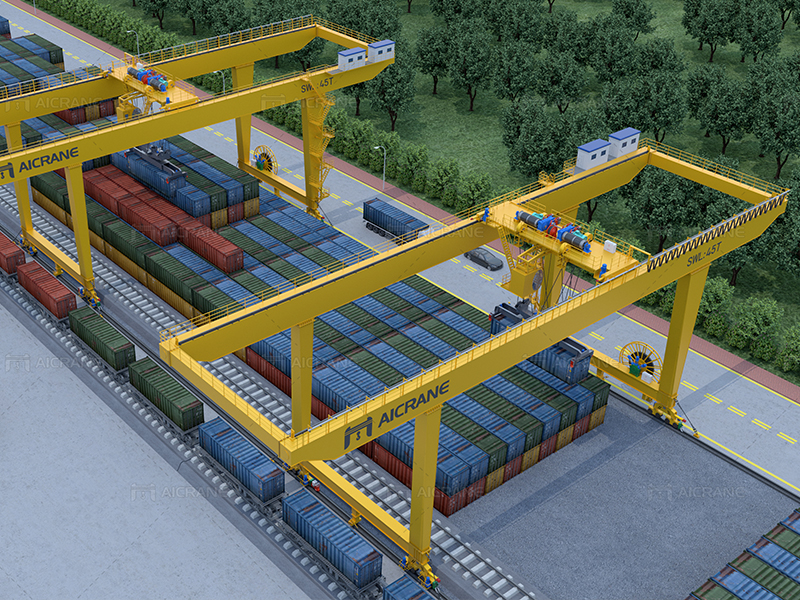

Rail-mounted gantry cranes (RMGCs) play a crucial role in material handling and container management at ports, terminals, and industrial facilities. The cost of acquiring and operating these cranes is a significant consideration for businesses. Understanding the factors that influence the cost of rail-mounted gantry cranes is essential for making informed decisions and optimizing investments. In this article, we will delve into the key factors that impact the cost of RMGCs.

Load Capacity and Span

The load capacity and span of a rail-mounted gantry crane are fundamental factors that directly influence its cost. RMGCs are designed to handle various load capacities, ranging from small containers to heavy-duty cargo. Additionally, the span, which refers to the distance between the crane’s legs, determines the coverage area. Cranes with higher load capacities and larger spans typically come with higher price tags due to the robust construction and engineering required to support heavier loads and cover larger areas.

Construction Material and Design

The choice of construction materials significantly affects the rail-mounted gantry crane cost. High-strength steel and advanced alloys are commonly used to ensure durability and structural integrity. Additionally, the design complexity, such as whether it is a single or double girder crane, impacts manufacturing costs. Sophisticated designs that incorporate advanced engineering features for improved performance and safety may incur higher expenses during both production and installation.

Hoisting Mechanism

The hoisting mechanism is a critical component of any gantry crane, determining its lifting capacity and efficiency. Different hoisting mechanisms, such as wire rope or chain hoists, come with varying costs. Additionally, cranes equipped with advanced lifting technologies, such as variable frequency drives (VFDs) for precise load control, may incur higher upfront costs. However, these technologies can result in long-term operational savings and increased efficiency.

Electrical Systems and Automation

The level of automation and the sophistication of the electrical systems significantly contribute to the overall cost of rail-mounted gantry cranes. Modern cranes often incorporate advanced automation features like computerized control systems, remote operation, and collision avoidance technology. While these features enhance productivity and safety, they also contribute to the overall cost of the crane. The choice between manual and automated systems depends on the specific operational requirements and budget considerations.

Environmental Considerations

Environmental factors can impact the cost of RMGCs, especially in regions with extreme weather conditions. The container gantry cranes designed to withstand harsh climates, such as high winds, corrosive salt air near coastal areas, or extreme temperatures, may require additional engineering and materials, leading to higher costs. Climate-specific modifications and protective measures can add to the overall expenses but are essential for ensuring the crane’s longevity and optimal performance in challenging environments.

Installation and Commissioning

The installation and commissioning process involves site preparation, foundation construction, and crane assembly. The complexity of these tasks, along with the need for specialized equipment and skilled labor, can influence the overall cost. Additionally, factors such as the location of the installation site, accessibility, and local regulations may impact the installation expenses. It is crucial to factor in these costs when budgeting for a rail-mounted gantry crane project.

Maintenance and Lifecycle Costs

While the initial acquisition cost is a significant consideration, businesses must also account for maintenance and lifecycle costs. High-quality components and regular maintenance contribute to the longevity and reliability of the crane. Choosing a crane with easily accessible and replaceable parts can reduce downtime and maintenance expenses over its operational life.

Conclusion

In conclusion, the cost of rail-mounted gantry cranes is influenced by a myriad of factors, each playing a crucial role in determining the overall investment required. Businesses must carefully assess their specific operational needs, considering factors such as load capacity, construction materials, hoisting mechanisms, automation levels, environmental conditions, installation requirements, and maintenance considerations. By understanding these factors, stakeholders can make informed decisions, optimize their investments, and ensure the long-term success of their material handling operations. For more info, visit https://steelmillcranes.com/